Tank Appurtenances and Fittings

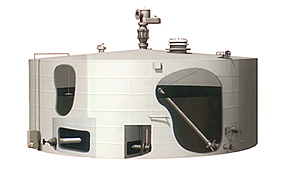

Cone Roof Tank built to API 620 for low pressure tank / API 650 for atmosphere tank.

Welded Steel Oil Storage Tanks built to API 650 - Tank having internal design pressure from Atmosphere pressure to 2.5 pounds per square inch gauge.

Welded Steel Oil Storage Tanks built to API 620 - Tank having internal design pressure not more than 15 pounds per square inch gauge.

Venting Atmospheric and Low-Pressure Storage Tanks to API 2000 - Tank Normal Venting and Emergency Venting Requirements.

What happen when Tank Venting Capacity are not correctly calculated

Causes of Overpressure or Vacuum (API 2000)

- Liquid movement into or out of the tank.

- Tank breathing due to weather changes (e.g., pressure and temperature changes).

- Fire exposure.

- Other circumstances resulting from equipment failures and operating errors.

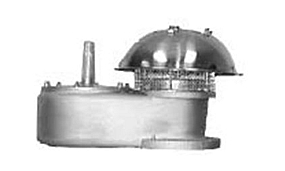

Why Breather Valve (also name as Pressure/Vacuum Relief Valve and Conservation Vent) is needed?

- Relieves excess pressure & vacuum created by thermal expansion & contraction

- Minimizes costly product evaporation losses during product movement, while protecting tanks against deformation caused by explosion or implosion

- Relieves vapor safely before reaching tank design pressure

- Tank is always maintained within design parameters

- Reduces EPA regulated emissions

- Complies with corporate emissions standards

Breather Valve product family:

- Spring-loaded Breather Valve; generally for 1 psig (700 mmH2O) or above set pressure

- Steam Jacketed Breather Valve

- Pressure Relief Valve

- Vacuum Relief Valve

- Pilot Operated Valve

Flame Arrester

- Prevents flame propagation into storage tank or vent piping from external source as required by NFPA & OSHA Standards

- Used where product may be heated above its flash point

- Used where product flash point is below 100 ºF

- Protects storage tanks & process from external ignition

- Provides a passive safety mechanism to prevent tank ignition & explosion

- Protects costly upstream equipment & processes

- Approved fro NEC Group D Vapors or Gases

- Size: 2” through 60”

- FM approved

Detonation Arrester

- Designed to withstand high velocity and high pressure flame fronts that may transition into detonations in long or complex vapor piping systems

- Required in Marine vapor recovery systems per Federal Regulation 42 CFR Part 154 Final Rule

- Recommended in vapor collection systems per NFPA 30 & API recommended practices

- DFAs are designed to stop deflagrations, stable detonations and over driven detonations

- Protects both upstream & downstream processes with bi-directional capabilities

- Replaces misapplied flame arresters in vapor piping systems

- Designed to withstand & extinguish stable & overdriven detonation flame fronts

- Isolates tanks in closed venting systems from a detonation or explosion in another tank or ignition source

- Withstands high pressure shock waves and quenches detonations

- Approved for NEC Group C and D Vapors or Gases

- Sizes: 2” through 24”

- U.S. Coast Guard Accepted and FM approved

- Provides easy access to storage tanks for product gauging or sampling

- “Quick-Clamp”* option allows for hands-free operation eliminating the need to remove work gloves or set down hand tools

- Spark-proof design and Teflon diaphragm ensures safe tight seal

- Sizes: 3”, 4”, 6”, 8”, 10”

- Easy access for gauging product level or temperature

- Cover is adaptable for self closing or not, and a tape gauge maker

- Sizes: 4”, 6”, 8”

- Emergency venting up to 1 oz./sq. in.

Weight Loaded Type

- Relieves emergency flow due to excessive venting requirement from a fire burning around a storage tank

- High Flow Capabilities

- Easy installation and convenient handling for inspection

- Tank examination requires no gasket replacement or unbolting

- Low base for overflow

- Sizes: 16”, 20”, 24” diameter manholes for tank inspection

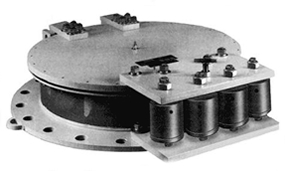

Pressure/Vaccuum Type

- Versatile design incorporates pressure and vacuum relief

- Reduced maintenance costs

- No need to unbolt vent for gasket replacement or tank examination

- Unique “self-energizing” diaphragm construction assures tight seal between pallets and seats

- 20” diameter manhole for tank inspection

- Low base for overflow

Magnetic Latching Type

- Magnetic latching eliminates excessive loading weights

- Unique diaphragm construction assures tight seal between pallet and seat

- It is an economical solution to costly and dangerous tank roof rupture problems

- Sizes: 10”, 16”, 20”

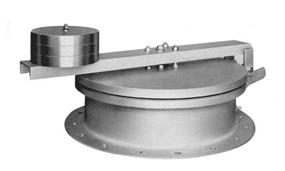

Hinged Type

- Relieves emergency flow due to excessive venting requirement from a fire burning around a storage tank

- Easy installation and handling for inspection

- No gasket replacement or unbolting is necessary, eliminating the expensive manpower needed to put conventional emergency vents back in operation

- Pallet construction permits a wide variety of pressure settings

- A flexible diaphragm affords a tight seal between the pallet and the corrosion resistant seat below set pressure. This also assures low leakage. The diaphragm is intended for normal ambient temperature storage

- Sizes: 10”, 16”, 20”, 24”

- Hinged Cover

Spring Loaded Type

- Spring Loaded Emergency Relief for Higher Design Pressures

- Simple, yet Rugged Design

- Superior Flow Characteristics

- 1 to 15 PSI Settings

- Sizes 16”, 20” and 24”

8" Magnetic Latching Type

- Low cost due to inexpensive weights for standard settings

- Magnetic latch assures instantaneous opening at release pressure and minimizes blowdown

- Innovative Expanda-Seal provides near zero leakage

- Settings: 0.5 psi to 2.75 psi

- Size: 8”

Cable Sheave Brackets (Open)

Benefits:

- The design of the base plate ensures centering of the load and stress on the tank shell rather than on the tank roof plates

- To ensure continued service and smooth operation, the cable sheave brackets use graphite bronze bearings

Cable Sheave Cases (Gas Tight Type)

Benefits:

- Can be adjusted for higher pressure or vacuum requirements by simply extending the length of the liquid seal

- For ease of operation and long service life, each sheave is bushed with bronze collar bushings

Benefits:

- The winch is smooth in operation and there is no back lash

- Minimal maintenance

- Simple, positive, smooth operation

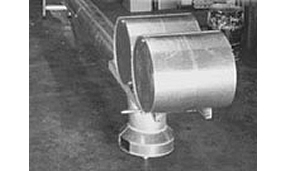

Floating suction assemblies are designed to draw off uncontaminated fuel from just below the surface of liquid storage tanks. The float ensures that water; foreign matter or sediment at the bottom of the tank is not withdrawn with the fuel. A pivot mounted, unsinkable aluminum or Stainless Steel float will provide the buoyancy required to keep the floating suction near the surface of the fluid.

The intake faces downwards and is fitted with a vortex breaker to provide anti-vortex protection and stop ingress of contamination from the bottom of the tank. Floating suctions are custom made to meet individual requirements of each installation. Diameters and lengths or heights of tanks must be provided. For horizontal tanks or tanks in which the height is much greater than the diameter, double arm design assemblies can be supplied.

Benefits:

- Closes automatically when fusible link releases

- Simplicity of design permits maximum flow and minimum wear

- New linkage design provides maximum clearance for high flow capacity

- Pilot pallet opens first, permitting minimum effort to open against maximum tank pressure in blocked line

- Sizes 4” through 24”

Model 92021 Automatic Tank Level Gauge is a float actuated tape driven gauge and by means of a digital counter indicates float travel accurately to 1/16 inch. Model 92021 meets all the specifications and recommendations of the American Petroleum Institute in accordance with API Bulletin 2509B.

Model 92302 Liquid Level Indicator is a reliable float actuated level gauging system. It is designed to provide reliable and virtually trouble-free service for installation not requiring accuracies better than ±1 inch.

Tank Level Gauging System

Tank Level Switches

Digester Gas Safety Equipment

Rupture Disc and Vent Panel

A rupture disk is a precision relief device designed to rupture at a predetermined pressure and temperature. It is means of providing protection for personnel and equipment. As such, it must be a safe device. Rupture disks are used where instantaneous and full opening of a pressure relief device is required. These devices are also utilized where “zero” leakage is required of a relief device. These devices can also be used in series as “quick opening” valves.

Metal Rupture Discs and Vent Panels

Graphite Discs

Burst Disc Detection Devices

In-line Sampling Valve

No dead space

Systems are designed to avoid dead space, improve cleanliness and avoid contamination.

Spring-to-close hand wheel

The actuators such as the Magic Hand Wheel provide an accurate flow and an intuitive use.

Many accessories and options

The quick connection and accessory interchangeability provide a customised solution to meet your needs.

Corrosion Monitoring System

What Is Corrosion Monitoring?

Corrosion monitoring can be described as "The regular measurement of corrosion or corrosivity as it effects an asset". It is most often used to make comparisons between actual and predicted corrosion rates, or for the evaluation of measures taken in prevention or mitigation. Some but not all corrosion monitors are sensitive to erosion that may occur in process plants due to high flow rates and entrained solids.

The asset may equally be a pipeline, a concrete bridge, a large HVAC system in a building, an offshore oil & gas facility or a printed circuit in a computer. When that part of the asset that is of interest is inaccessible, simple methods such as visual inspection or manual measurement cannot be used and special techniques must be introduced. This is especially true of continuous processes where internal corrosion may advance at a rapid rate and lead to catastrophic failure long before traditional "inspection" can detect it. Corrosion Monitoring has therefore, come to be associated mainly with internal corrosion of process equipment, although there are a wide range of other applications where the techniques can do valuable work.

Why monitor?

Corrosion is not an isolated phenomenon; it is a natural process that attacks any material, particularly metals, under the right conditions. It is therefore prudent to expect corrosion; to look for it and to be prepared to prevent it once a tendency to corrode is discovered.

However carefully a process plant is designed and the materials of construction selected the risk of corrosion is only reduced. Experience tells us, often with horrific consequences, that it is never eliminated. Failures due to corrosion can be costly to repair, costly in terms of lost or contaminated product, costly in terms of pollution and environmental damage (which in turn may result in fines or closure of the installation), and ultimately it may be costly in terms of human safety.

Fear of corrosion can result in over-design or selection of materials which are not otherwise ideal. By adding to capital cost this may make projects commercially unattractive or unfeasible, so that ultra-safe design alone is not a correct response. Many projects are designed with corrosion allowances in the calculations and monitoring in place to evaluate actual corrosion rates against those predicted, allowing action in good time if a variance is observed. In addition to this valuable service, corrosion monitoring can be used as a pro-active tool to assist with operating the plant in a more effective way, thereby prolonging life and gaining optimum throughput. For example, in the oil & gas industry the produced hydrocarbon liquids or gas and associated water are to some degree variable in composition, temperature, pressure and flow rate. This causes complex corrosion and erosion problems in the production process equipment that are often episodic in nature.

Most operators seek to solve these problems by using some form of chemical treatment in conjunction with careful materials selection. In each case a fine balance must be found between the cost of treatment, the rate of plant deterioration and the rate of production if the business objective is to be met. Corrosion Monitoring is a key tool for this, advising when to treat and what the corrosion rate will be in any given mode of operation. This is information that can drive a continuous improvement process.

Corrosion monitoring methods

In order to incorporate corrosion monitoring into a strategy it is necessary to understand the basics of CORROSION MONITORING METHODS and the tools available. The range of available monitoring methods is wide, but they fall into three main groups: -

- Metal Loss types: which measure the physical loss of material due to corrosion or erosion by either physical or electrical means.

- Electrochemical types: which measure the corrosivity of an environment independent of actual material loss.

- Supporting Analyses: Iron counts, biofilm testing, pH monitoring etc., a range of sampling based laboratory techniques which add to the overall understanding of the system performance. These are not directly relevant to this document, but should be considered part of the tool-kit available to the technical team.

Range of Products:

- Access Fittings

- Corrosion Coupons

- Chemical Injection & Sampling equipments

- Retractable Access systems

- Retriever Tools & Services Valves

- Electrical Resistance (ER) Probes

- Linear Polarisation Resistance (LPR) Probes

- Galvanic Probes / Hydrogen Probes

- Real Time Monitoring Data Collection Units

- Corrosion Database Management Systems

- Interface to PC and Scada / DCS

Gas Leak and Detection System

Gastron established in 1992 manufactures combustible and toxic gas detectors using catalytic combustion, thermal conductivity and electro-chemical type. Acquiring the approval from KR (Korean Register of Shipping) and KOSHA (Korea Occupational Safety and Health Agency), KOFEIC (Korea Fire Equipment Inspection Corporation).

Flammable Gas Detector

Oxygen & Toxic Gas Detector

Auction Suction Type

Multi-Channel Control Unit

Rain Cover and Pipe mounting Bracket Accessories